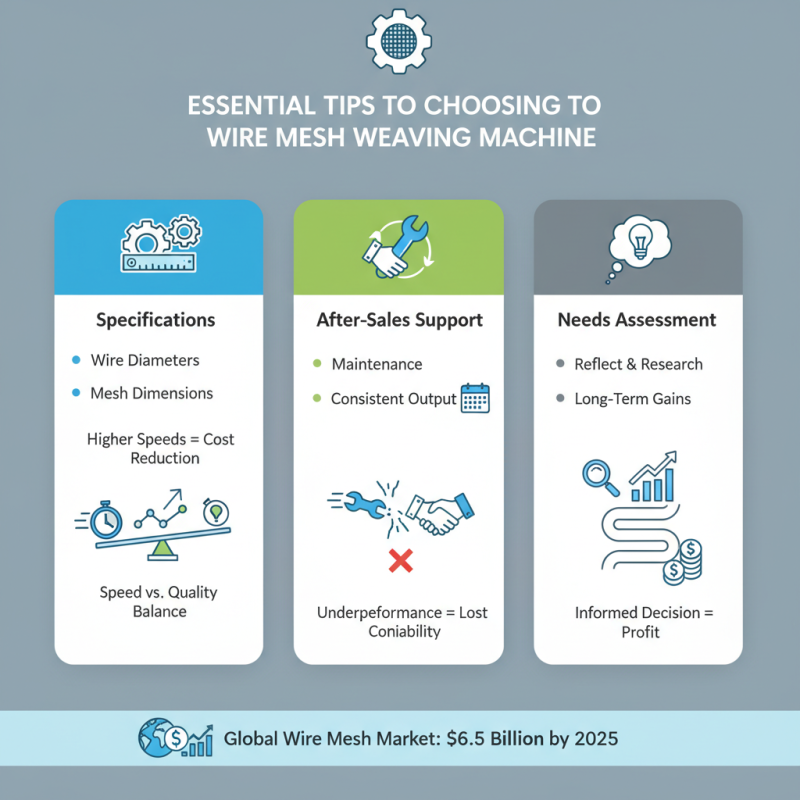

Choosing the right wire mesh weaving machine is critical for manufacturers. The global wire mesh market is projected to reach $6.5 billion by 2025, highlighting the increasing demand for quality machinery. The machine you choose affects production efficiency and product quality.

Consider the specifications that matter most. Wire diameters, mesh dimensions, and weaving speed directly influence output. Industry studies show that machines with higher speeds can reduce costs significantly. However, a faster machine may not always mean better quality. This balance is crucial in decision-making.

Do not underestimate after-sales support. Without proper maintenance, even a top-tier wire mesh weaving machine can underperform. Inconsistent output may result in lost contracts. Reflect on your needs and capabilities before making a decision. Investing time in research can ensure long-term gains.

Wire mesh weaving machines are crucial in various industries. They create mesh for construction, agriculture, and filtration. Understanding the basics of these machines is essential for making informed decisions. Reports suggest that the global wire mesh market could reach $7.8 billion by 2025, growing at a CAGR of 5.2%. This highlights the increasing demand for quality weaving machines.

When choosing a wire mesh weaving machine, consider the type of materials you will use. Machines vary in compatibility with different wire types. For instance, stainless steel, galvanized steel, and copper each require specific setup. A lack of flexibility in machine choice may lead to production delays. Industry experts suggest evaluating your future needs. You don’t want to choose a machine that quickly becomes outdated. For example, automation features are increasingly important. They enhance efficiency but can complicate maintenance.

Quality and durability are also critical factors. Not all machines maintain consistent performance over time. Regular wear and tear can compromise mesh quality. Investing in a reliable machine can save costs long-term. However, the initial purchase may be challenging for some. Balancing budget with quality is often a struggle for businesses. Understanding this landscape can empower better decision-making in wire mesh production.

When selecting a wire mesh weaving machine, there are several key features to consider. Pay attention to the machine's weaving speed. A higher speed often leads to increased productivity. However, too much speed can compromise quality. You need to find a balance. The ability to produce a variety of mesh sizes is also important. A versatile machine can handle different projects and materials. This flexibility can enhance your operations.

Another significant feature is ease of operation. The machine should be user-friendly. Control systems should be intuitive. Complicated settings may lead to mistakes and inefficiencies. Durability is vital too. Machines face wear and tear over time. Investing in a robust machine can save you costs in the long run.

Consider the maintenance needs as well. Some machines require frequent servicing. This can disrupt production flow. It’s wise to pick a machine that has lower maintenance demands. Ultimately, thoroughly evaluating these aspects will guide you towards making a more informed choice.

When choosing a wire mesh weaving machine, understanding the types available is crucial. Each type caters to different applications. For instance, a plain weave machine is great for making standard mesh, while a twill weave machine offers enhanced strength. According to industry reports, the global wire mesh market is projected to grow by 4.5% annually, highlighting the rising demand for specialized machines.

Tip: Evaluate your production volume before selecting a machine. A higher capacity machine may deliver efficiency for large projects. However, it could lead to over-investment if your needs are modest. For smaller operations, a manual or semi-automatic machine might suffice.

Another option is woven wire mesh machines, ideal for creating intricate patterns. They're commonly used in architecture and design industries. Yet, complexities in operation can be a headache. Ensuring a balance between quality and usability is essential. An operator's skill level also impacts the machine's performance.

Tip: Inspect the machine’s specifications against your requirements. Misalignment between expectations and capabilities can lead to frustration. Optimal choices stem from a clear understanding of your specific needs and market dynamics. The right machine should align with both production goals and budget constraints.

When selecting a wire mesh weaving machine, quality and durability are paramount. Industry reports indicate that nearly 30% of machine failures stem from low-quality components. A sturdy frame can make a significant difference, especially for heavy-duty applications. Materials used in construction, like high-grade steel, typically provide better longevity. Consider machines with a robust design, as they can withstand high tension and frequent use.

Maintenance play a crucial role in a machine's lifespan. Many operators overlook regular servicing, which leads to premature wear. According to the Machinery Journal, a machine well-maintained can last up to 50% longer than one that isn't. Look for ease of access to critical components for regular checks. Machines with user-friendly designs can help reduce maintenance errors.

Another consideration is the machine's performance under different conditions. Many weaving machines perform well in ideal environments but struggle in harsher settings. Evaluating how a machine handles temperature fluctuations and humidity is essential. Gathering feedback from existing users can provide insights that statistics alone might miss. Always weigh the pros and cons before making a decision.

Choosing the right wire mesh weaving machine can be overwhelming, especially when considering budget constraints. The market offers machines ranging from low-cost options to high-end equipment. Determining what fits your needs and budget is crucial for maximizing your investment.

A recent industry report indicated that the average cost of a wire mesh weaving machine is around $15,000 to $50,000. However, a significant number of buyers opt for machines within the $10,000 to $20,000 range. These cost-effective options can deliver satisfactory performance without overspending. Remember, cheap machines may lead to higher operational costs. Their maintenance can become a financial burden.

Cost isn't just about initial price. Ongoing expenses, such as electricity and manpower, need consideration. Look into machines that offer energy efficiency. This can greatly reduce long-term costs. Research shows that efficient machines can save up to 30% on energy bills. Additional costs, like spare parts and technical support, also matter. Investing a bit more for reliable support can yield better results.