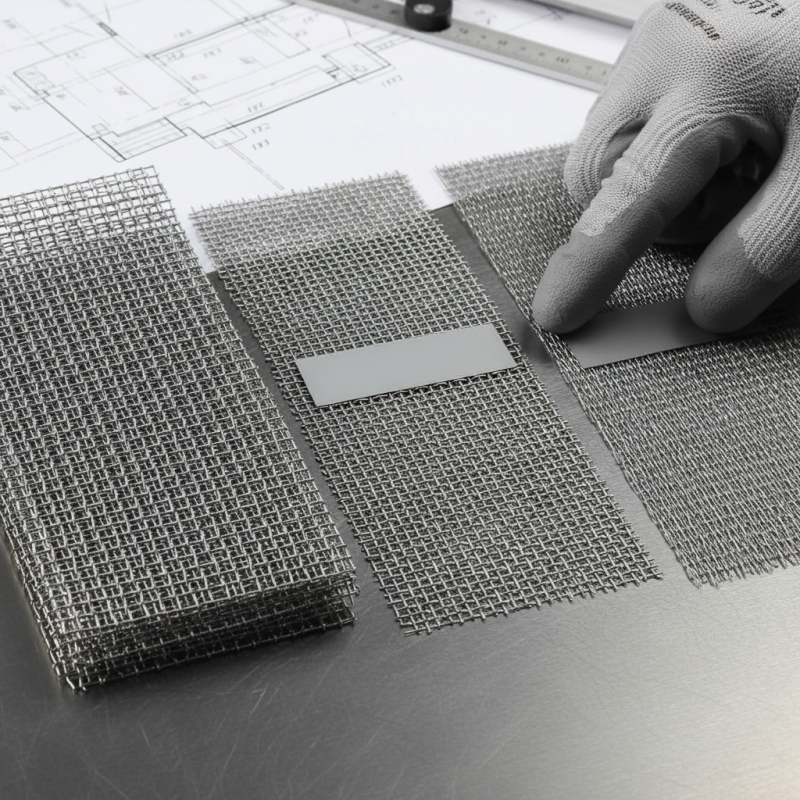

Choosing the best stainless steel woven wire mesh can be challenging. This material is popular for its durability and versatility. However, not all stainless steel woven wire mesh is created equal.

When selecting this type of mesh, consider various factors. The wire gauge affects strength and flexibility. A thicker gauge typically offers more durability. The mesh opening size also plays a crucial role. Smaller openings can filter finer particles, while larger ones allow for better airflow.

Additionally, the type of stainless steel used impacts corrosion resistance. 304 and 316 grades are common choices, but they serve different purposes. Reflect on your specific needs carefully. A mistake in selection can lead to unsatisfactory performance. Thus, take time to research and evaluate options thoroughly.

stainless steel woven wire mesh comes in various types, each with distinct properties. The choice of mesh depends largely on its intended application. For instance, the 304 stainless steel mesh is widely used due to its excellent corrosion resistance. According to industry reports, nearly 70% of wire mesh users prefer this grade for general use.

In contrast, the 316 grade offers superior chemical resistance. This makes it ideal for harsh environments. Many industries, such as marine and chemical processing, favor 316 due to its durability. Data shows that over 50% of those in demanding applications choose 316 for its longevity.

Mesh size and wire diameter are crucial factors. A finer mesh size can filter smaller particles effectively, while a thicker wire can enhance strength. However, selecting the right combination can be challenging. Not all specifications may meet regulatory standards, leading to potential compliance issues. Always consider the specific needs and limitations of your project to ensure optimal safety and functionality.

| Mesh Type | Wire Diameter | Opening Size | Weave Type | Applications |

|---|---|---|---|---|

| Plain Weave | 0.5 mm | 1.0 mm | Plain | Filtration, Sieving |

| Twill Weave | 0.6 mm | 0.8 mm | Twill | Industrial Filtration, Screening |

| Dutch Weave | 0.4 mm | 0.5 mm | Dutch | Filtration of Fine Particles, Food Industry |

| Locking Weave | 0.7 mm | 1.2 mm | Locking | Security Fencing, Safety Screens |

When selecting stainless steel woven wire mesh, several factors come into play. The mesh's weave pattern affects its strength and flexibility. A tighter weave usually means stronger material. Consider the application. For filtration, finer mesh is crucial. It can capture smaller particles effectively.

Next, think about the wire diameter. Thicker wires provide more strength but may reduce flexibility. This choice can impact your project. Evaluate the environment where the mesh will be used. High temperatures or corrosive elements may require specific types of stainless steel.

Don't overlook the importance of mesh size and opening dimensions. These specifications affect performance and durability. If too large, it won't serve its purpose. Take your time to examine these details carefully. Small oversights can lead to significant issues down the line. Adjusting your choices might be necessary as you gather more information. Choose wisely for the best results.

When choosing stainless steel woven wire mesh, understanding different grades is essential. The most common grades are 304 and 316. Grade 304 is versatile and widely used. It is resistant to many corrosive environments. This makes it ideal for indoor applications. However, it may not perform well in harsh outdoor conditions.

On the other hand, grade 316 offers better corrosion resistance. It contains molybdenum, which enhances its durability. This makes it suitable for marine environments. Using grade 316 can be more costly. You might need to weigh the cost against the benefits. Sometimes, making a choice feels overwhelming. Consider the application and the environment before deciding.

Other grades exist, such as 430, which is magnetic. This grade is less expensive, but it lacks high corrosion resistance. Different applications demand different properties. Reflect on what truly meets your needs. Don’t rush into a decision. Collect samples, test them, and evaluate performance. Your choice should align with long-term goals and specific requirements.

Choosing the right stainless steel woven wire mesh involves careful consideration of mesh openings and wire diameter. The size of the openings determines the flow of materials through the mesh. For instance, a 0.5mm opening is ideal for filtration applications, while larger openings, such as 2mm, might be suitable for screens in construction. According to industry reports, the right mesh can boost productivity by up to 30% in manufacturing settings. However, selecting the wrong size could cause inefficiencies or failures.

Wire diameter plays a critical role in the mesh's strength and durability. Thicker wires, often ranging from 0.1mm to 1mm, provide enhanced support and resistance to wear. A study indicated that a wire diameter of 0.5mm can withstand approximately 250 N of tensile force. Yet, thinner wires might be necessary for applications needing flexibility or minimal weight. Many users overlook the impact of wire diameter on operational effectiveness, leading to suboptimal performance in challenging environments.

In evaluating your needs, consider the specific application and environment. Some applications may require high corrosion resistance, while others may focus on ease of cleaning. Ignoring these details can compromise the mesh's effectiveness over time. Balancing between opening size and wire diameter is an ongoing challenge. Each decision must align with the requirements of your specific project and industry standards, which vary widely.

When considering the purchase of stainless steel woven wire mesh, cost and availability are key factors. Prices vary widely based on mesh size, material quality, and supplier. It’s wise to gather multiple quotes. This helps in understanding the market better. A lower price might be tempting, but it often reflects compromises in quality. Always inquire about the specifications.

Availability can also affect your decision. Some sizes and styles are easier to find than others. Think about your project timelines. If a specific mesh type isn't readily available, it could delay your project. Local suppliers may stock more common options, while specialty items might take longer to source. Estimating delivery times is critical.

Buying wire mesh shouldn't be rushed. Track your needs and compare options. Make sure the mesh fits your intended use and context. Reflect on your choices, and don’t be afraid to ask questions. Consider durability as well. Sometimes, spending a little more upfront can save you money in the long run.